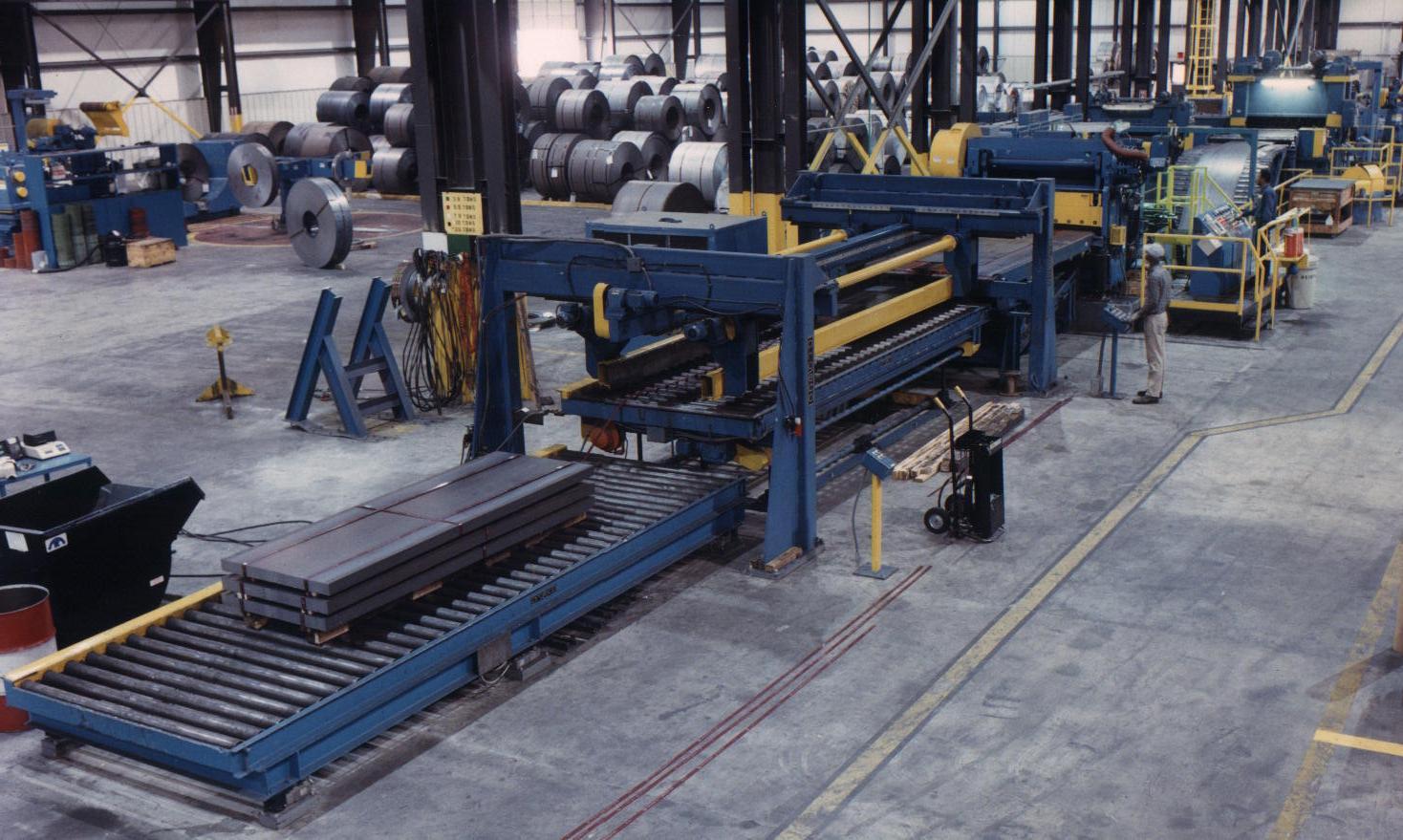

Cut-to-Length Lines

Equipment has developed very high expertise.

Normally used for high quality requirements of sheets for Automotives and white goods, in these lines, the precision leveller runs continuously at a constant speed and pushes the material in a loop. A low inertia Feed Roll pulls the material out of the loop at high speed and stops at the exact required length, ensuring accurate cut lengths. Length accuracy of ±0.30mm and diagonal accuracy of ±0.5mm can be achieved, depending on the selection of electrical controls. These lines can cut sheets at the rate upto 60 cuts/minute and speeds upto 110mpm.

These lines are the ideal choice for customers who do not require the high production rates associated with Roll Feed Lines and want to process heavier gauge, non-surface critical materials.

In these lines, the leveller/flattener works in a start-stop mode. Strips upto 20mm thick and 2000mm wide can be processed on such lines.

These lines are ideal for processing soft or highly surface critical materials. In these lines, the strip does not have to stop at any point of time, hus preventing any marking of the strip.

These lines have shearing dies which accelerate to match the strip speed and cut at exact length in four-post underdriven presses.

These are used for thinner strips at fast speeds. Typical application is Galvanised and/or colour coated strips for roofing materials. The precision leveller runs at a constant speed. The shear blades are mounted on two eccentrics geared together and activated automatically to match the sheet speed at the exact length for shearing. Speeds upto 150mpm can be attained on such lines.

Special Features

-

01Precision LevellersEsmech Equipment offers 4High, 5High and 6High multi-roll precision levellers suitable for strip thicknesses as low as 0.10mm and as high as 6.0mm. Built to high precision, these levellers are designed to be adjusted "on the fly" or "as you level". A number of adjustable back up roll banks ensure high quality of levelling. Quick change cassette type models are also available to increase the range of strip thickness in the same line.

-

02Mechanical down-cut shearsEsmech Equipment offers high speed shears with a cut cycle time as low as 200 milliseconds. The clearance between blades can be adjusted very easily and precisely with pre-callibrated single handwheel setting. The over-crank design of shears enable stacking of sheets right under the shear for damage-free handling of cut-sheets in the stacker.

-

03Stacking SystemsEsmech Equipment offer air cushion type or drop type or combination air-drop type stackers. End discharge or side discharge systems coupled with extra feature of stack storage, weighment and conveying can also be provided. Multiple stackers can be also be provided to eliminate stack change-over time for higher productivity.

-

04Tail Out FunctionAutomatic tail out function is provided to monitor operations of the entire line to enable unaided and damage free cutting ypto the last possible full length sheet after the tail-out of the coil from the uncoiler.